Features:

Dewfall proof

Fast start-up, FSU

Isochronous applications, IRT

Media-Redundancy Protocol, MRP

PNO Encoder Profile, CL 3/4

Preset “on the fly”

Salt water resistant

Shared Device

SIL3, PLe

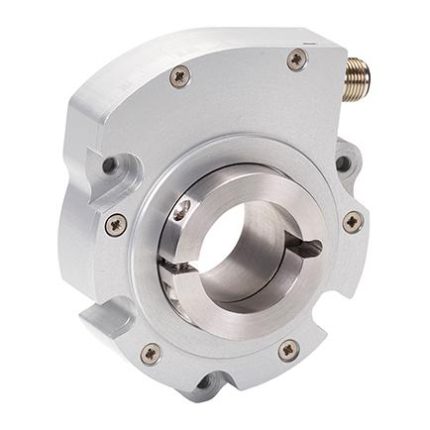

TR-Electronic CDS582MM – EPN + FS3 Absolute Encoder

Absolute-Encoder CDS582MM – EPN + FS3

(C) Compact Encoder, (S) Blind shaft, PROFINET IO

SKU:

K-CDS58_2FS-PN-2

Category: Mutlak kodlayıcılar

Description

Additional information

| Marka |

|---|

About TR-Electronic

TR-Electronic, otomasyon teknolojisi için ölçüm ve kontrol sistemleri üretir ve geliştirir. TR-Electronic, farklı uygulama türleri için yüksek kaliteli standart ürünler veya özelleştirilmiş çözümler olarak doğru döner kodlayıcıları, doğrusal kodlayıcıları ve sürücüleri tedarik eder. TR-Electronic'teki uzmanlar, fikirleri ve geliştirme bilgileri, yaratıcı ürünlerin ve genişleyen küresel başarının temelidir. TR-Electronic ürün yelpazesi, işlevsellik, kalite ve maliyet etkinliği açısından rekabet avantajına sahiptir.

FİYAT AL

Teklif almak için lütfen başvurunuzu info@project-master.tr adresine göndererek, ihtiyaç duyduğunuz pozisyonları ve şirket detaylarını belirtin.

Specification

General data

Nominal voltage - Specific value 24 VDC - Limit values, min/max 10/30 VDC Nominal current, typically - Specific value 110 mA - Specific value 130 mA with second interface - Condition unloaded Supply - SELV/PELV IEC 60364-4-41 - In case of UL / CSA approval according to NEC Class 2 Device design - Type Multi-Turn - Redundant scanning system yes, double - Design magnetic/magnetic Total resolution <= 29 Bit Number of steps per revolution <= 8192 = 13 bit resolution Number of revolutions <= 65536 Accuracy (functional) 8 Bit, Single-Turn; 1.406 ° PROFINET IO - Interface - PROFINET IO – Device IEC 61158, IEC 61784-1 - Physical Layer Fast Ethernet, ISO/IEC 8802-3 - PROFINET-Specification V2.3 - Conformance Class B, C - Real-Time-Classes Class 1, 2 (RT), Class 3 (IRT) - PROFIsafe-Profile No. 3.192b - PROFIsafe-Profile PROFIsafe V2.4 (BP) - PROFIsafe-Profile PROFIsafe V2.6.1 (XP) - Media Redundancy Protocol, MRP yes, is supported - PNO Encoder-Profile Class 3 and 4, V4.2 - Fast Start-Up (FSU) 3-times faster start-up SSI - Interface - Equipment Optional interface - SSI-Clock input RS-422; 2-wire - SSI-Data output RS-422, 2-wire - SSI-Clock frequency <= 1MHz - SSI-Mono time, typically 15 µs, 20 µs, 50 µs, 500 µs - Protocol, TR-specific Function information + CRC - Output code Binary, Gray - Number of data bits 8…29 - Type of parametrization programmable - MTTFd, SSI 150 a Transmission rate - Specific value 100 MBit/s Cycle time >= 1000 µs (IRT/RT) - Not safety related 0.5 ms - Safety related 3 ms Parameter/Function, changeable Integration time Preset parameter Scaling parameter Monitoring window Counting direction Velocity parameter Type of parametrization programmable Programming - Tool Fieldbus-Device TCI Device Tool Functional safety - Safety principle Redundance with cross compare - SIL-Standardization DIN EN 61508 / DIN EN 62061 - SIL-Standardization DIN EN 61800-5-2 - SIL-Level SIL3 / SIL CL 3 - PL-Standardization DIN EN ISO 13849 - Performance-Level (PL) PLe / Cat. 4 - Service life 20 Years - PFH / PFH [D] 1.00E-9 1/h - PFH / PFH [D] PFH: DIN EN 61508-4 - PFH / PFH [D] PFH [D]: DIN EN ISO 13849-1 - PFDav, T = 20 a 8.50E-5 - MTTFd 170 a, high - DCavg 98 %, high/middle - Mode High demand, continuous - Proof-Test-Interval T1 = 20 Years - Accuracy (safety) 7 Bit, Single-Turn; 2.812 ° Safety functions - DIN EN 61800-5-2 SLP (safely-limited position) - DIN EN 61800-5-2 SDI (safe direction) - DIN EN 61800-5-2 SCA (safe cam) - DIN EN 61800-5-2 SS1 (safe stop 1) - DIN EN 61800-5-2 SS2 (safe stop 2) - DIN EN 61800-5-2 SOS (safe operating stop) - DIN EN 61800-5-2 SLS (safely-limited speed) - DIN EN 61800-5-2 SSR (safe speed range) - DIN EN 61800-5-2 SSM (safe speed monitor) Internal process safety time - Profisafe instances: , Times: 2, DAT <= 14 ms, WCDT <= 7 ms - Profisafe instances: , Times: 4, DAT <= 18 ms, WCDT <= 8 ms Maximum Speed, mechanically <= 6000 1/min Shaft load, axial/radial Own mass Bearing life time >= 3.9E+10 revolutions Bearing life time - Parameter - Speed 3000 1/min - Operating temperature 60 °C Shaft type - Shaft diameter [mm] 8 - Shaft diameter [mm] 10 - Shaft diameter [mm] 12 - Shaft diameter [mm] 14 - Shaft diameter [mm] 15 - Shaft forming Parallel key/Groove Angular acceleration <= 10E+4 rad/s² Moment of inertia, worst-case <= 9.0E-6 kg m² at shaft diameter 10 mm depending from shaft forming Start-up torque, worst-case <= 3.7 Ncm (IP65,-20 °C,+6 σ) <= 10 Ncm (IP67,-20 °C,+6 σ) at shaft diameter 10 mm depending from shaft forming Circular runout ± 0.3 mm (static, radial) Circular runout, TH mounting - TH Torque holder - Type1 (static/dynamic) Type1 axial ± 0.13/0.1 mm - Type1 (static/dynamic) Type1 radial ± 0.25/0.1 mm - Equipment optional Mass, typically 0.3…0.5 kg Isolation voltage 500 V

Nominal voltage - Specific value 24 VDC - Limit values, min/max 10/30 VDC Nominal current, typically - Specific value 110 mA - Specific value 130 mA with second interface - Condition unloaded Supply - SELV/PELV IEC 60364-4-41 - In case of UL / CSA approval according to NEC Class 2 Device design - Type Multi-Turn - Redundant scanning system yes, double - Design magnetic/magnetic Total resolution <= 29 Bit Number of steps per revolution <= 8192 = 13 bit resolution Number of revolutions <= 65536 Accuracy (functional) 8 Bit, Single-Turn; 1.406 ° PROFINET IO - Interface - PROFINET IO – Device IEC 61158, IEC 61784-1 - Physical Layer Fast Ethernet, ISO/IEC 8802-3 - PROFINET-Specification V2.3 - Conformance Class B, C - Real-Time-Classes Class 1, 2 (RT), Class 3 (IRT) - PROFIsafe-Profile No. 3.192b - PROFIsafe-Profile PROFIsafe V2.4 (BP) - PROFIsafe-Profile PROFIsafe V2.6.1 (XP) - Media Redundancy Protocol, MRP yes, is supported - PNO Encoder-Profile Class 3 and 4, V4.2 - Fast Start-Up (FSU) 3-times faster start-up SSI - Interface - Equipment Optional interface - SSI-Clock input RS-422; 2-wire - SSI-Data output RS-422, 2-wire - SSI-Clock frequency <= 1MHz - SSI-Mono time, typically 15 µs, 20 µs, 50 µs, 500 µs - Protocol, TR-specific Function information + CRC - Output code Binary, Gray - Number of data bits 8…29 - Type of parametrization programmable - MTTFd, SSI 150 a Transmission rate - Specific value 100 MBit/s Cycle time >= 1000 µs (IRT/RT) - Not safety related 0.5 ms - Safety related 3 ms Parameter/Function, changeable Integration time Preset parameter Scaling parameter Monitoring window Counting direction Velocity parameter Type of parametrization programmable Programming - Tool Fieldbus-Device TCI Device Tool Functional safety - Safety principle Redundance with cross compare - SIL-Standardization DIN EN 61508 / DIN EN 62061 - SIL-Standardization DIN EN 61800-5-2 - SIL-Level SIL3 / SIL CL 3 - PL-Standardization DIN EN ISO 13849 - Performance-Level (PL) PLe / Cat. 4 - Service life 20 Years - PFH / PFH [D] 1.00E-9 1/h - PFH / PFH [D] PFH: DIN EN 61508-4 - PFH / PFH [D] PFH [D]: DIN EN ISO 13849-1 - PFDav, T = 20 a 8.50E-5 - MTTFd 170 a, high - DCavg 98 %, high/middle - Mode High demand, continuous - Proof-Test-Interval T1 = 20 Years - Accuracy (safety) 7 Bit, Single-Turn; 2.812 ° Safety functions - DIN EN 61800-5-2 SLP (safely-limited position) - DIN EN 61800-5-2 SDI (safe direction) - DIN EN 61800-5-2 SCA (safe cam) - DIN EN 61800-5-2 SS1 (safe stop 1) - DIN EN 61800-5-2 SS2 (safe stop 2) - DIN EN 61800-5-2 SOS (safe operating stop) - DIN EN 61800-5-2 SLS (safely-limited speed) - DIN EN 61800-5-2 SSR (safe speed range) - DIN EN 61800-5-2 SSM (safe speed monitor) Internal process safety time - Profisafe instances: , Times: 2, DAT <= 14 ms, WCDT <= 7 ms - Profisafe instances: , Times: 4, DAT <= 18 ms, WCDT <= 8 ms Maximum Speed, mechanically <= 6000 1/min Shaft load, axial/radial Own mass Bearing life time >= 3.9E+10 revolutions Bearing life time - Parameter - Speed 3000 1/min - Operating temperature 60 °C Shaft type - Shaft diameter [mm] 8 - Shaft diameter [mm] 10 - Shaft diameter [mm] 12 - Shaft diameter [mm] 14 - Shaft diameter [mm] 15 - Shaft forming Parallel key/Groove Angular acceleration <= 10E+4 rad/s² Moment of inertia, worst-case <= 9.0E-6 kg m² at shaft diameter 10 mm depending from shaft forming Start-up torque, worst-case <= 3.7 Ncm (IP65,-20 °C,+6 σ) <= 10 Ncm (IP67,-20 °C,+6 σ) at shaft diameter 10 mm depending from shaft forming Circular runout ± 0.3 mm (static, radial) Circular runout, TH mounting - TH Torque holder - Type1 (static/dynamic) Type1 axial ± 0.13/0.1 mm - Type1 (static/dynamic) Type1 radial ± 0.25/0.1 mm - Equipment optional Mass, typically 0.3…0.5 kg Isolation voltage 500 V